Framework of Success for Digital Twins' Projects

Digital Twins to help manufacturer save time, money and resources

Digital twins allow you to build a data based replica of your entire industrial process. Its real time monitoring of machines or entire operations, helps you to identify potential hiccups, to optimize every stage and to prevent the outcome variations.

There are numerous applications. In the critical asset management field, such as energy or utilities sectors, it opens the path to new maintenance strategies. Going from reactive maintenance to predictive or even prescriptive maintenance plans.

In manufacturing you will be able to deploy programs to reduce the scrape rate, predict end-of-line product quality and to increase your Overall Equipment Effectiveness.

In the same way, the outcome of an industrial data-driven project can vary from AI model deployed at the edge for automated adjustments of parameters, to stream or batch analytics and information visualizations for Kanban Meetings or Root Cause Analysis.

What are the Key Success Factors for a successful Digital Twin project in industry?

Each manufacturing line is specific, having its own organization, technology requirements, ROI formula, and so on. In the same way, the expected deliverable and the industrial environment in which it will be introduced, is business specific.

That’s why, before starting this first scoping of technological solutions, it’s precious to define the business’ objectives and operational contexts. Here, the onboarding of shopfloor stakeholders is strategical to pave the way to success. Allowing them to understand the main data concepts it’s key to identify applications that will have return on investment starting day one.

This new awareness makes operational teams excited about digital, smoothing the obstacles to change.

Finally when all the dimensions are aligned, you have clear the requirements and decision criteria to select the solution(s) and partner(s), and to define the project organization tailored to your specific context.

Never forget, that beyond technological hype, the most relevant solution is the one which serves yours objectives!

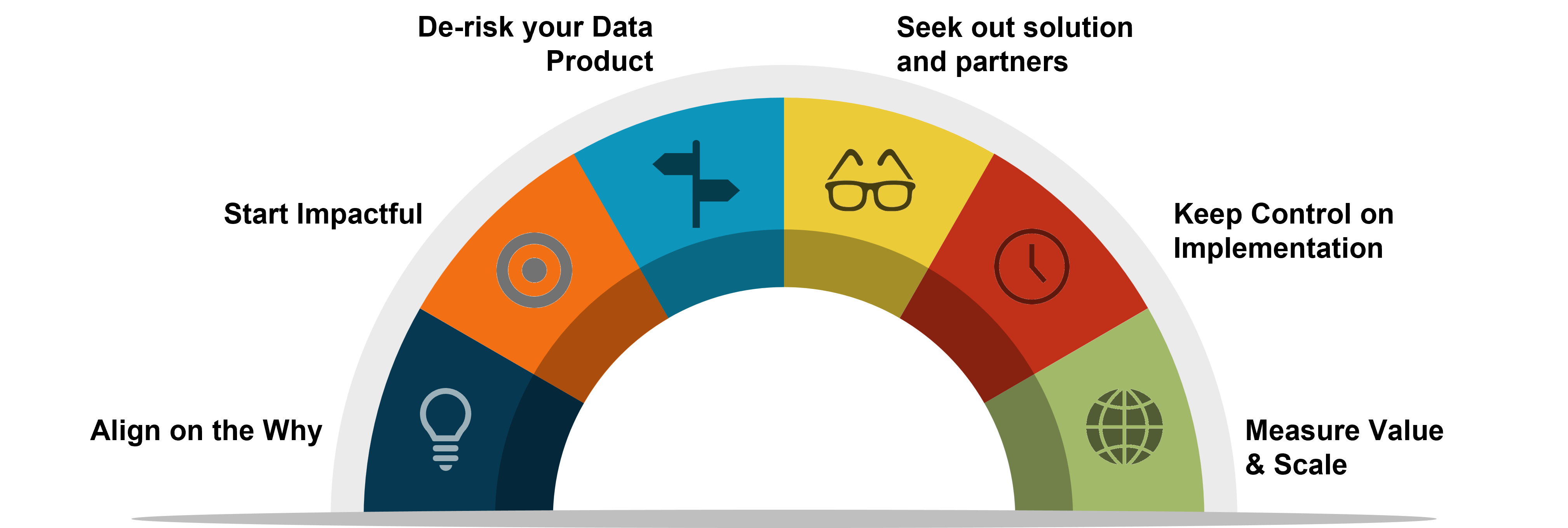

Digital Twins Framework of Success

Align on the Why

Understanding the Data “concepts”

Envisioning applications

Weighting with industrial benefits

Start Impactful

Formalizing in 5 days the specifications of the 1st application, the remediation plan for identified blockers and calculating the ROI

De-risk your Data Product

Mobilizing industrial experts and tech teams to create a single view of the project while mapping it from end to end

Seek out solution and partners

Beyond technology hype selecting the solutions that natively fit your specificities

Keep Control on Implementation

A Project Management based on achieving the defined Industrial Outcome

Measure Value & Scale

After production deployment, validate the ROI and build a “fact-proof” roll out